Get your sensors on your network.

Any sensor.

Any network.

Alert on abnormal sensor readings.

Capture equipment event changes.

Record sensor readings in real-time.

Key Features of the SHARC IoT sensor adapter.

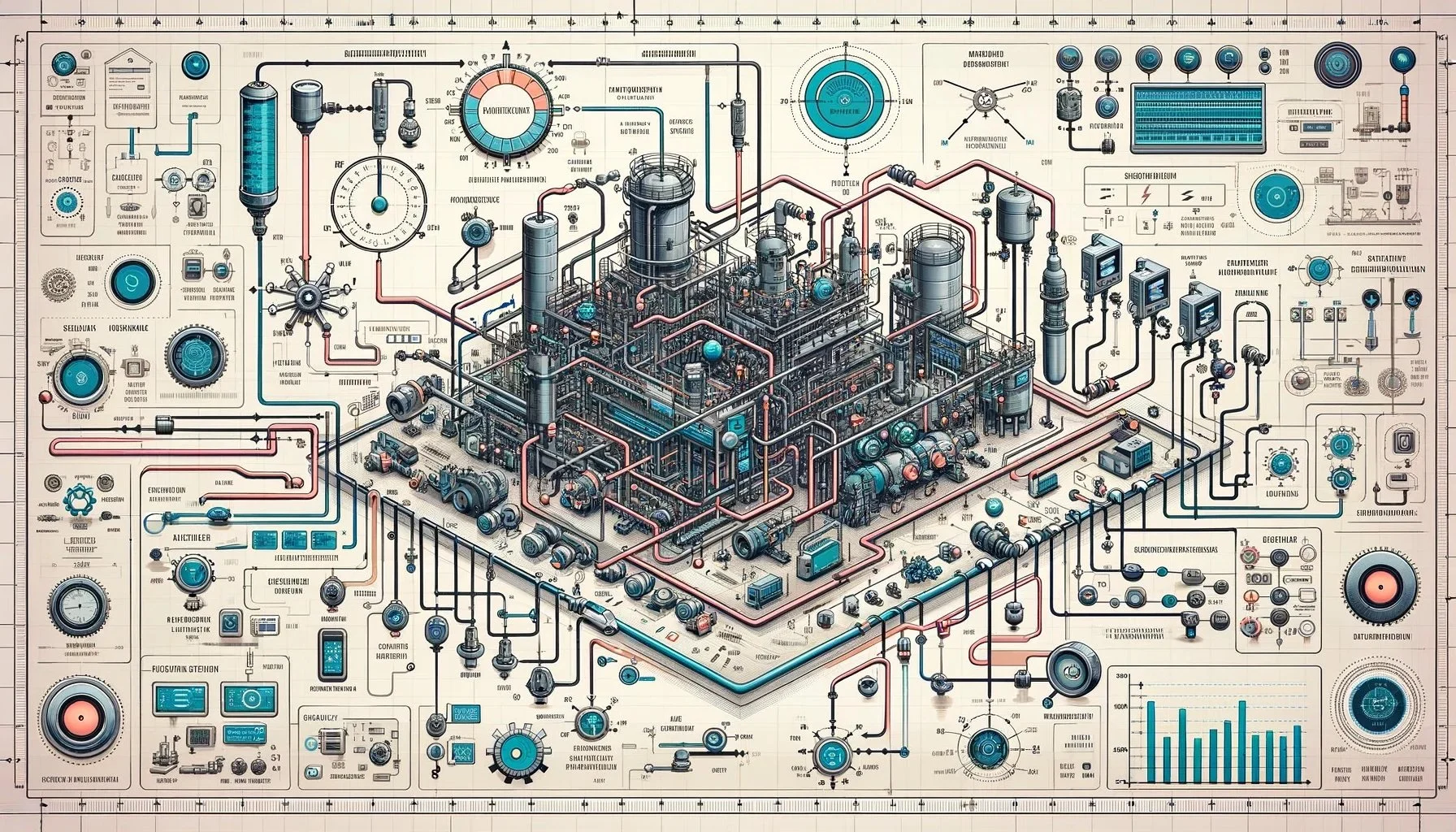

Universal Compatibility. The SHARC IoT sensor adapter supports various machine types and system platforms ensuring that you can connect multiple assets with ease.

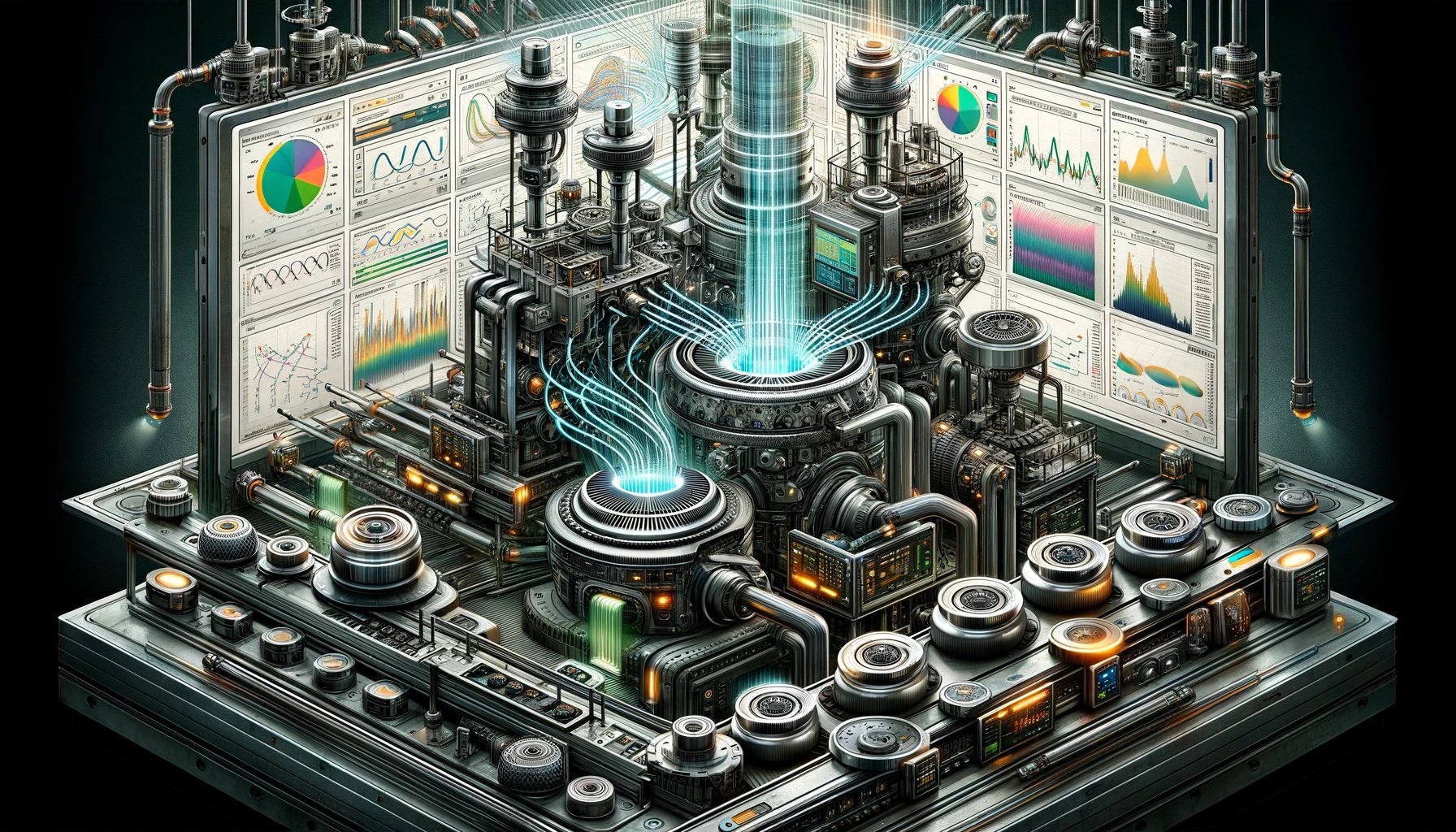

Real-Time Data Monitoring. Gain instant insights into your operations with our real-time data collection capabilities, helping you make informed decisions quickly.

User-Friendly Interface. With an intuitive design, the SHARC makes it easy to monitor and manage your connected devices, even for those without extensive technical expertise.

Scalability. As your operations grow, the SHARC is built to scale with your needs, allowing for easy expansion and integration of new devices.

Predictive Maintenance. The data gathered through the SHARC IoT sensor adapter enables predictive maintenance strategies, helping you identify potential issues before they become critical, ultimately reducing downtime and costly machine failure.

The SHARC is a digital industry 4.0 transformation solution designed to optimize processes by providing the ability to monitor, analyze, and sustain success in the real-time.

Choose what to measure.

Select a digital or analog industrial sensor from any manufacturer to capture observations in the real world.

Measure facility air pressure using a pressure transducer.

Measure the condition of a clean room using a temperature and humidity sensor.

Measure production throughput or machine state using a proximity, laser sensor, or an existing PLC output.

Measure motor and electrical loads using a current transformer.

The possibilities are endless.

Ingest sensor telemetry into any software platform.

We don’t lock you into any specific software. The SHARC communicates seamlessly with all platforms due to modern data payload and transmission standards, such as JSON and MQTT.

Kepware, Ignition, Splunk, InfluxDB, Fuuz, Grafana, IoTDB, Node-Red… The list goes on and on.

The time to democratize access to industrial data was long overdue.

Data at your fingertips within minutes.

Manage your SHARC fleet with our iPhone and desktop applications.

Give us a try, other end users and software platform vendors have. They’re all satisfied with how quickly we can deliver insights. Something not easily achievable until now.

We have come to love and hate the Unified Namspace. So we couldn’t figure out what to do besides give our customers a 25% discount. Apply the UNS discount code during checkout.

Expediency and cost.

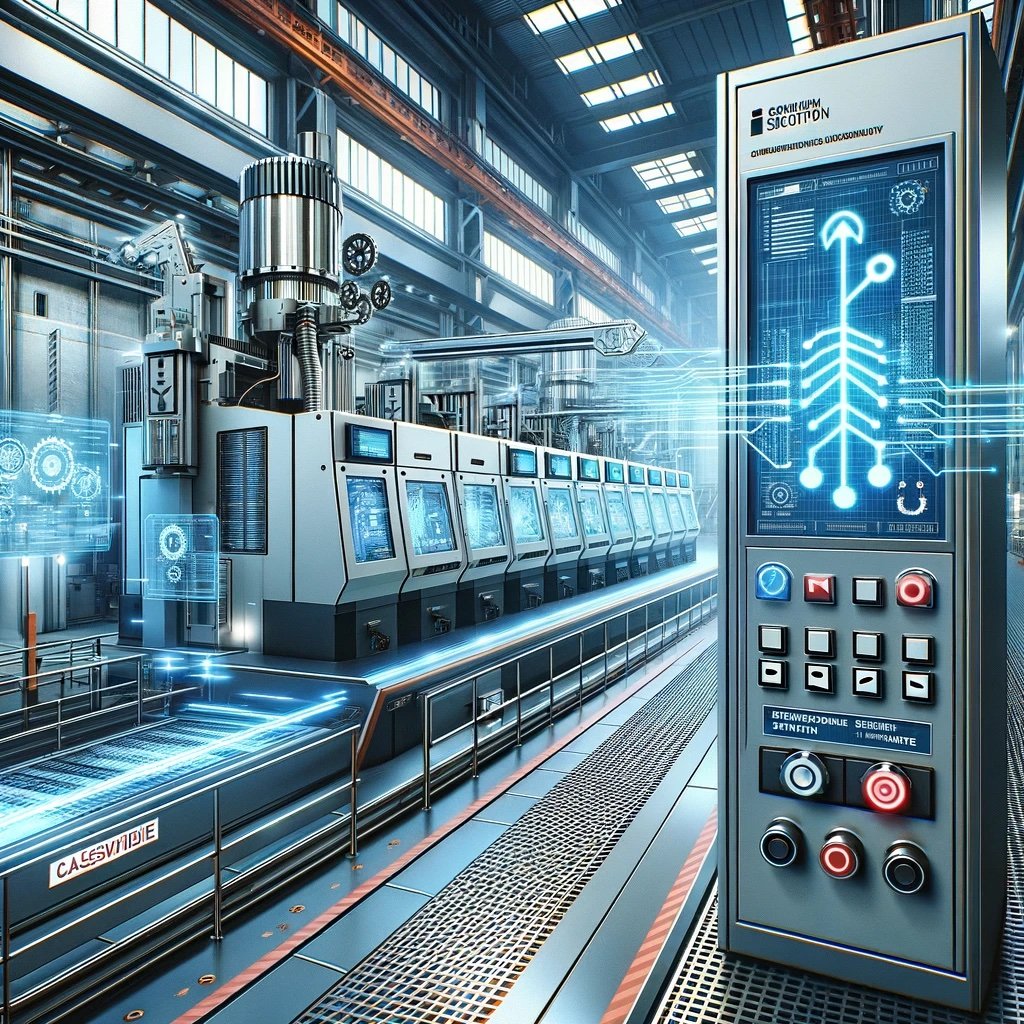

A customer asked us for two simple metrics.

What percentage of time is the machine utilized?

What is the operating time of the laser?

After consulting with the OEM, the base cost of establishing machine connectivity would be tenfold that of two SHARCs.

The SHARC choice was a no-brainer. We delivered the metrics into their CMMS to assist with optimizing essential maintenance functions.

Integration into existing models.

The SHARC is perfect for supplementing missing sensor measurements and observations into existing device and data models. Because the data is JSON transported over MQTT, interoperability standards like the MTConnect, OPC-UA, and SparkplugB allow direct ingestion of additional data points with minimal effort.

Production behind closed doors.

In classified environments, the SHARC removes cyber security risks. You choose precisely what to measure and nothing more. As a one-way data diode, maintenance plans become data-driven, and new attack surfaces are never introduced.

Simple. Accessible.

Where IT and OT intersect.

Still have questions?

Contact us, and we’ll help you through your SHARC and fact-finding journey.